Birotor Meter

Birotor Meter

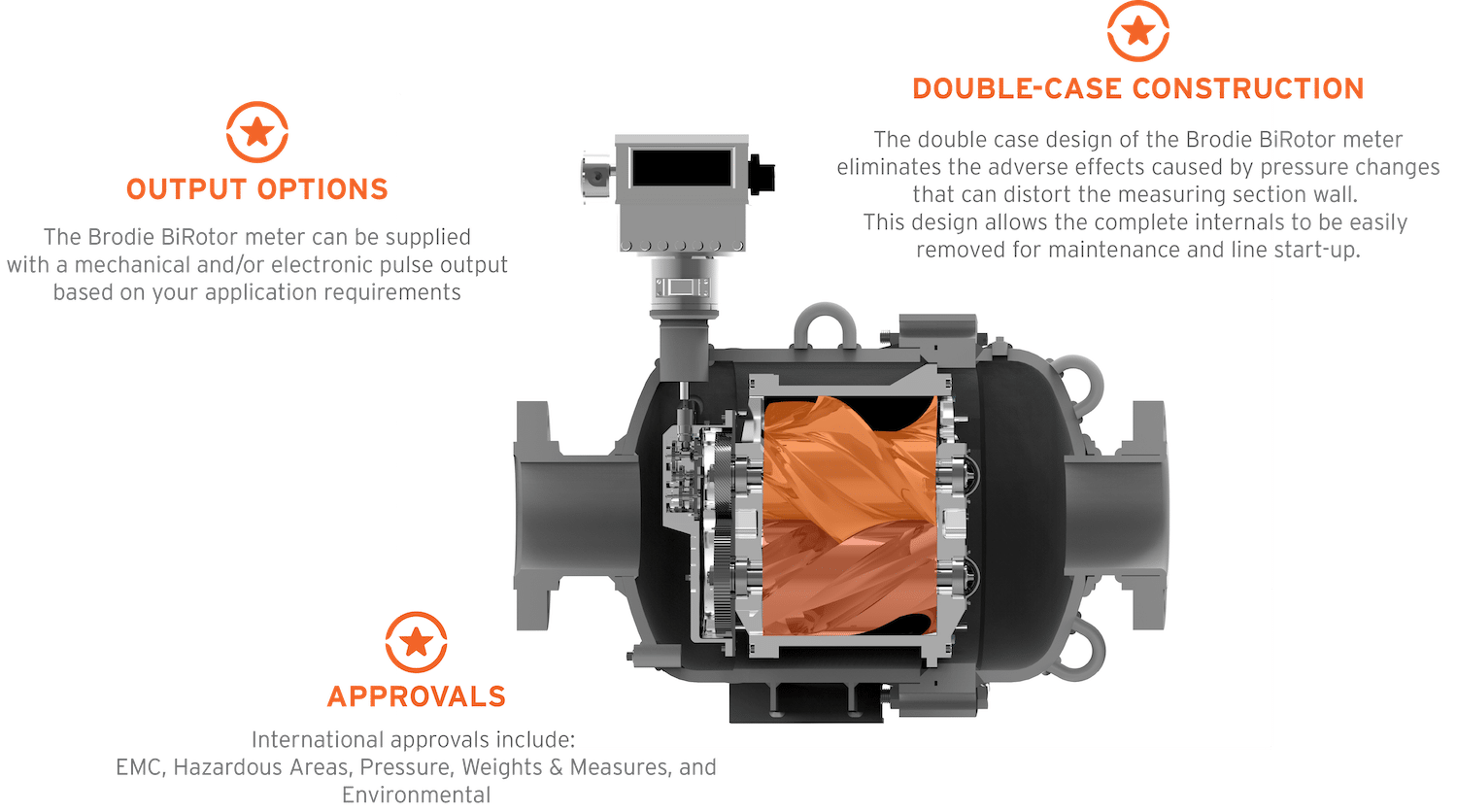

The Brodie Birotor Meter is a positive displacement meter utilized in the most demanding applications requiring accuracy, long life and ruggedness. The legacy Birotor is available in two configurations, integral mechanical registration or electronic pulse output.

The mechanical meter utilizes a gear train located outside the measuring unit chamber to transfer mechanical rotation of the rotors to a mechanical or electronic register for totalization of liquid throughput.

For P-Style (Pulse output) units, a pulse verification gear located outside the measuring unit chamber conveys mechanical rotation of the rotors to the sensor and to the electronic register for totalization of liquid throughput.

Birotor Meter

Technical Specifications

| Model Code | B03 | B04 | B05 | B06 | B07 | B08 | |

| Line Size and End connections | 1.5″ ANSI | 2″ ANSI 150 | 2″ ANSI 150 300 600 | 3″ ANSI 150 300 600 | 3″ ANSI 150 300 600 | 4″ ANSI 150 300 600 | |

| Flow Range | 6-60 GPM 23-227 LPM | 10-100 GPM 38-379 LPM | 15-150 GPM 57-567 LPM | 25-250 GPM 95-946 LPM | 43-425 GPM 161-1608 LPM | 60-600 GPM 227-2271 LPM | |

| Max Working Pressure @ 100F (38C) | ANSI 150 | 150 PSI 10.3 Bar | 150 PSI 10.3 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | |

| ANSI 300 | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | |||

| ANSI 600 | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | |||

| Linearity | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | |

| Repeatability | 0.04% | 0.04% | 0.04% | 0.04% | 0.04% | 0.04% | |

| Material | Meter Housing | Steel | Steel | Steel | Steel | Steel | Steel |

| Flanges | Steel | Steel | Steel | Steel | Steel | Steel | |

| Model Code | B09 | B10 | B11 | B12 | B13 | B17 APL | |

| Line Size and End connections | 6″ ANSI | 8″ ANSI | 10″ ANSI | 12″ ANSI | 16″ ANSI | 3″ ANSI | |

| 150 300 600 | 150 300 600 | 150 300 600 | 150 300 600 | 150 300 600 | 150 300 600 | ||

| Flow Range | 100-1000 GPM 379-3785 LPM | 214-2142 BPH 34-341 M3/H | 357-3571 BPH 57-567 M3/H | 1000-5000 BPH 158-794 M3/H | 2500-12500 BPH 207-2066 M3/H | 85-425 GPM 322-1609 LPM | |

| Max Working Pressure @ 100F (38C) | ANSI 150 | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar |

| ANSI 300 | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | |

| ANSI 600 | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | |

| Linearity | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.25% | |

| Repeatability | 0.04% | 0.04% | 0.04% | 0.04% | 0.04% | 0.04% | |

| Material | Meter Housing | Steel | Steel | Steel | Steel | Steel | Steel |

| Flanges | Steel | Steel | Steel | Steel | Steel | Steel | |

| Model Code | B18 APL | B19 APL | B20 APL | B21 APL | B22 APL | B23 APL | |

| Line Size and End connections | 4″ ANSI 150 300 600 | 6″ ANSI 150 300 600 | 8″ ANSI 150 300 600 | 10″ ANSI 150 300 600 | 12″ ANSI 150 300 600 | 16″ ANSI 150 300 600 | |

| Flow Range | 140-700 GPM 530-2649 LPM | 240-1200 GPM 908-4542 LPM | 600-3000 BPH 95-476 M3/H | 943-4714 BPH 150-749 M3/H | 1250-6250 BPH 200-993 M3/H | 2600-13000 BPH 413-2066 M3/H | |

| Max Working Pressure @ 100F (38C) | ANSI 150 | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar |

| ANSI 300 | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | |

| ANSI 600 | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | |

| Linearity | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | +/-0.15% | |

| Repeatability | 0.04% | 0.04% | 0.04% | 0.04% | 0.04% | 0.04% | |

| Material | Meter Housing | Steel | Steel | Steel | Steel | Steel | Steel |

| Flanges | Steel | Steel | Steel | Steel | Steel | Steel | |

| Model Code | HCB10 | HCB11 | HCB12 | ||||

| Line Size and End connections | 8″ ANSI 150 300 600 | 10″ ANSI 150 300 600 | 12″ ANSI 150 300 600 | ||||

| Flow Range | 357-3571 BPH 57.7-567 M3/H | 500-5000 BPH 80-794 M3/H | 945-9450 BPH 150-1500 M3/H | ||||

| Max Working Pressure @ 100F (38C) | ANSI 150 | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | 285 PSI 19.5 Bar | |||

| ANSI 300 | 740 PSI 51 Bar | 740 PSI 51 Bar | 740 PSI 51 Bar | ||||

| ANSI 600 | 1480 PSI 100 Bar | 1480 PSI 100 Bar | 1480 PSI 100 Bar | ||||

| Linearity | +/-0.15% | +/-0.15% | +/-0.15% | ||||

| Repeatability | 0.04% | 0.04% | 0.04% | ||||

| Material | Meter Housing | Steel | Steel | Steel | |||

| Flanges | Steel | Steel | Steel | ||||

Technical Highlights

Life Cycle

NO METAL TO METAL CONTACT

Timing gears, manufactured from hardened tungsten steel, are the only contacting components within the Birotor meter. The measurement chamber and rotors are machined to include precision tolerances and have no metal to metal contact. Engineered to provide extended durability, the Birotor meter optimizes your operation with durability and performance.

Timing gears, manufactured from hardened tungsten steel, are the only contacting components within the Birotor meter. The measurement chamber and rotors are machined to include precision tolerances and have no metal to metal contact. Engineered to provide extended durability, the Birotor meter optimizes your operation with durability and performance.

Timing gears, manufactured from hardened tungsten steel, are the only contacting components within the Birotor meter. The measurement chamber and rotors are machined to include precision tolerances and have no metal to metal contact. Engineered to provide extended durability, the Birotor meter optimizes your operation with durability and performance.

Timing gears, manufactured from hardened tungsten steel, are the only contacting components within the Birotor meter. The measurement chamber and rotors are machined to include precision tolerances and have no metal to metal contact. Engineered to provide extended durability, the Birotor meter optimizes your operation with durability and performance.