BV89 TWO-STAGE CONTROL VALVE

The BV89 Control Valve is a normally closed, two-stage electrical valve designed for precise, accurate shut-off of petroleum products. In applications such as petroleum loading racks where product delivery is predetermined and metered, the valve reduces flowrate before final shutoff to minimize pressure surge and line shock.

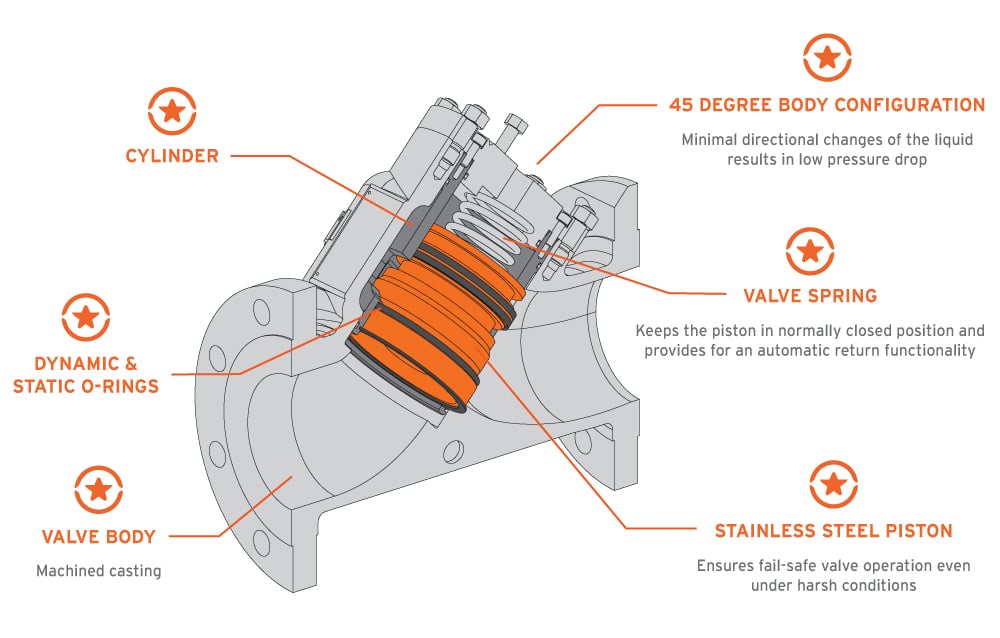

Brodie Valve Assembly

Brodie Valve Disassembly

BV89 TWO-STAGE CONTROL VALVE

| Valve Size | 2″ | 3″ | 4″ | 6″ | ||

| Dimensions | 150 # | Inches | 10¼ | 11 | 13 | 17 |

| [flange to flange] | MM | 260 | 279 | 330 | 432 | |

| Dimensions | 300 # | Inches | 13⅛ | 14½ | 17⅞ | |

| [flange to flange] | MM | 333 | 368 | 454 | ||

| Capacity | CV-GPM | 71 | 187 | 237 | 590 | |

| Pressure | 150 # | SEP | SEP | SEP | CRN, PED | |

| Approvals | 300 # | PED | PED | PED |

CHECK VALVE FUNCTIONALITY

The valve piston spring, biased to the closed position, has equal front and rear surface areas. This means that every Brodie Model BV valve has check valve functionality, with bubble-tight shut-off – no additional system check valve is required to prevent reverse flow. The valve will only open when upstream pressure is sufficient to overcome spring force.

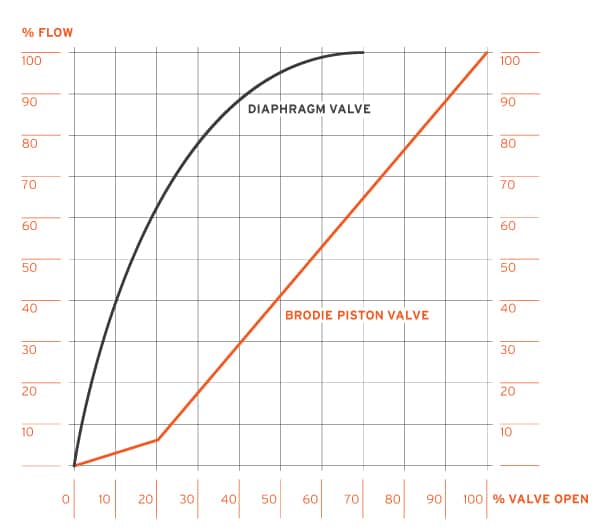

BRODIE VS DIAPHRAGM VALVES

There are many advantages in using piston-operated control valves as opposed to diaphragm-operated valves, including:

- High flow capacity – lower pressure drop

- Optimum control at low flow gives better batching control

- Simple O-ring sealing – no special diaphragms

- Alternative O-rings easily obtainable per product specifications

Designed to meet the challenges for today’s petroleum and environmental needs, Brodie’s positive sealing and linear action control valves provide uniform speed of response and leak-proof performance.

REDUCED COST OF OWNERSHIP

- Long service life, only one moving part

- Cylinder can be removed without removing body from the line

- Cylinder assemblies available as replacement kits

SECURITY & CONTROL

- Automatic shutoff for emergency protection

- Pressure monitoring at all times

UNIFORM SPEED OF RESPONSE

Flow modulation avoids delayed response and valve slam.

- Pilot operated

- Positive Sealing/Zero Leakage

- Modular construction/easy inline service

- Adjustable opening and closing speeds – prevents damaging shock pressure

- Linear action control for uniform fast speed of control

- Simple design without diaphragms

- Common valve body and internal mechanism simplifies spare parts inventory

- Multiple control functions can be performed with one valve