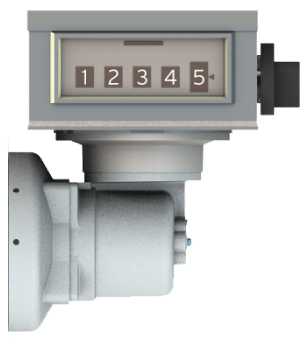

Oval Gear Meter

The Brodie Oval Gear Flowmeters are positive displacement meters designed for use in the Chemical Processing, Industrial, Food and Beverage, and Hydrocarbon processing industries.

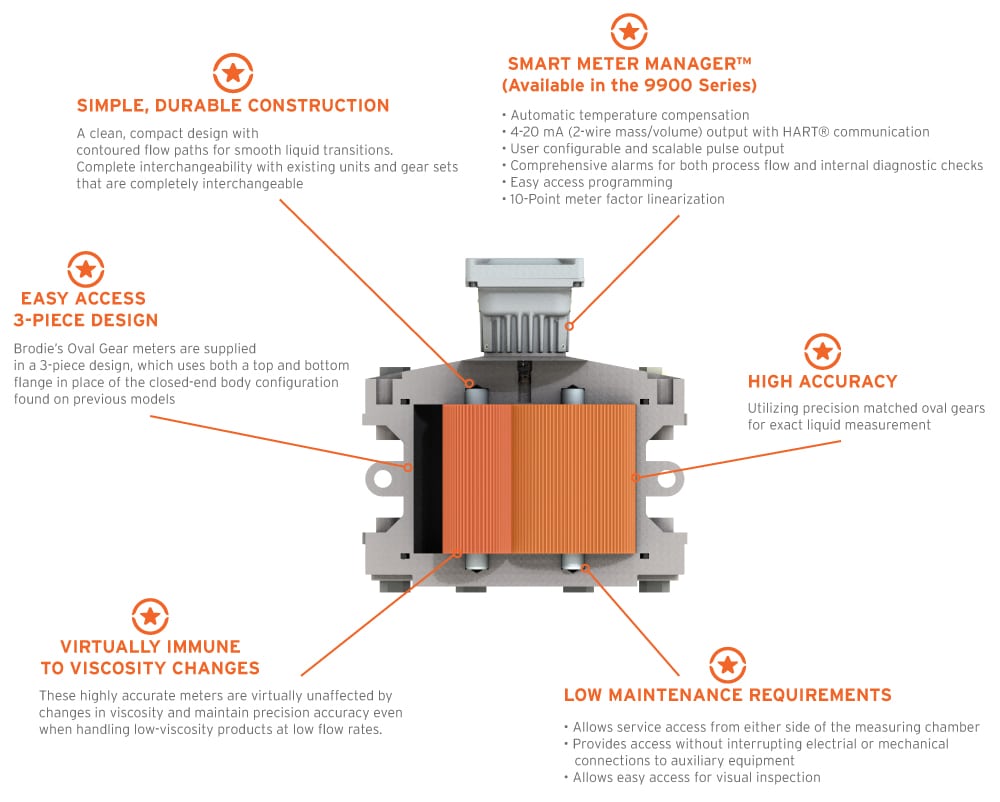

Utilizing precision matched oval gears for exact liquid measurement, these high-performance meters are virtually unaffected by changes in viscosity and maintain accuracy even when handling low viscosity products at low flow rates.

The Oval Gear Meter is available in three output configurations:

- Mechanical

- Smart Meter Manager

- Power Pulse

Oval Gear Meter

| Connection Size | Model Number | Flow Rates | Cold Water | Hot Water 140°-230°F | LPG 0.2 cP | Gasoline 0.3-0.7 cP | Kerosene 0.8-1.8 cP | Light Oil 2-4 cP | Heavy Oil 5-300 cP |

|---|---|---|---|---|---|---|---|---|---|

| ½” | 9X52 | GPM | 1.3-6.6 | 1.8-4.4 | 3.1-8 | 1.8-8 | 1.3-8 | 0.7-9 | 0.4-9 |

| LPM | 5-25 | 6.7-17 | 12-30 | 6.7-30 | 5-30 | 2.5-33 | 1.3-33 | ||

| 1” | 9X53 | GPM | 2.4-13 | 3.1-8.8 | 4.8-16 | 3.1-16 | 2.4-16 | 1.2-17 | 0.7-17 |

| LPM | 9-50 | 12-33 | 18-60 | 12-60 | 9.2-60 | 5-67 | 2.5-67 | ||

| 1” | 9X55 | GPM | 4.4-31 | 5.3-22 | 7.9-37 | 5.3-37 | 4.4-37 | 1.8-44 | 1-44 |

| LPM | 17-117 | 20-83 | 30-142 | 20-142 | 17-141 | 6.7-167 | 4.3-167 | ||

| 1½” | 9X56 | GPM | 8.8-62 | 11-44 | 15-75 | 11-75 | 8.8-75 | 4-88 | 2.6-88 |

| LPM | 33-233 | 42-167 | 58-283 | 42-283 | 33-283 | 15-333 | 10-333 | ||

| 2” | 9X57 | GPM | 18-132 | 22-88 | 35-154 | 35-154 | 18-154 | 8.8-176 | 5-176 |

| LPM | 67-500 | 83-333 | 133-583 | 133-583 | 67-583 | 33-667 | 20-667 | ||

| 3” | 9X59 | GPM | 35 – 264 | 44 – 176 | 66 – 308 | 44 – 308 | 35 – 308 | 26 – 396 | 18 – 396 |

| LPM | 133-1000 | 167-667 | 250-1167 | 167-1167 | 133-1167 | 100-1500 | 67-1500 |

| Flange Materials of Construction | ANSI Flange (lbs.) | Pressure Rating at 100° (38°C) | |

|---|---|---|---|

| PSI | kPa | ||

| Steel | 150 RF | 285 | 1965 |

| Steel | 300 RF | 740 | 5102 |

| 316 Stn. Stl. | 150 RF | 275 | 1896 |

| 316 Stn. Stl. | 300 RF | 720 | 4964 |

| Model Number | Connection Size | Mesh | Microns |

|---|---|---|---|

| 9X52 | ½” | 80 | 150 |

| 9X53 | 1” | 80 | 150 |

| 9X55 | 1” | 60 | 250 |

| 9X56 | 1½” | 60 | 250 |

| 9X57 | 2” | 40 | 350 |

| 9X59 | 3” | 40 | 350 |

- Standard viscosity ranges from 0.2 to 300 cP

- High viscosity is classified as above 300 cP

- Standard: 1/2” to 3” CLASS 150 ANSI flange Optional: 1/2” to 3” CLASS 300 ANSI flange, DIN, Tri-Clover

- Body, Rotors, and Shafts: Stainless steel

Rotor bearings: Carbon (std.) or for corrosive/abrasive

product, Waukesha (opt.) or carbon/ceramic (opt.)

O-rings: Viton (std.); Teflon, EPR, silicon (opt.)

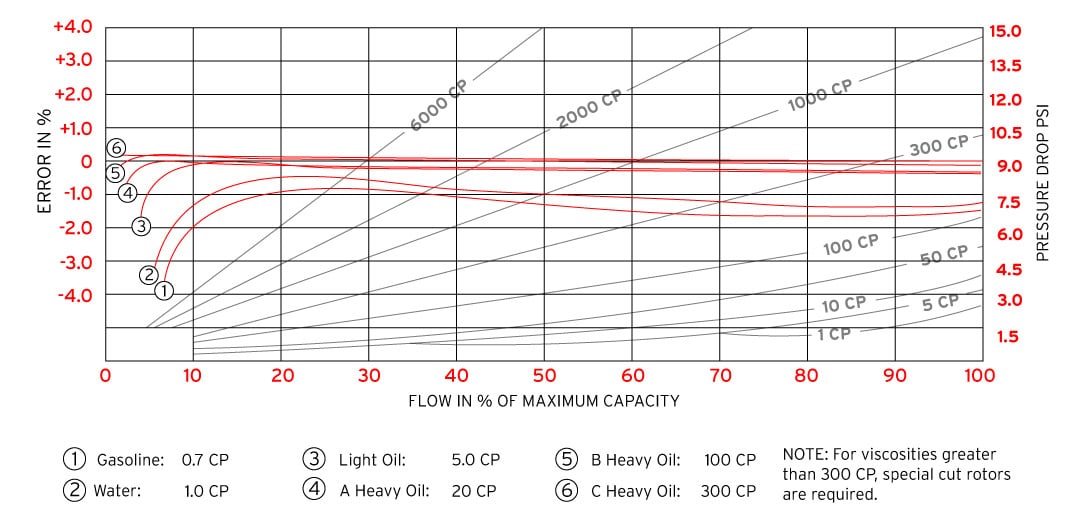

Viscosity changes have little effect on Brodie’s Oval Gear Flowmeter. At full flow, the change in error % is negligible.

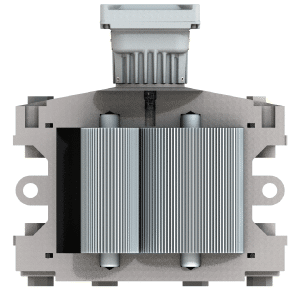

Brodie’s Oval Gear meters are supplied in a 3-piece design, which uses both a top and bottom flange in place of the closed-end body configuration found on previous models. This 3-piece design meets or exceeds all of the design and performance specifications of the original oval gear meter while offering several distinct advantages.

Mechanical power transmission for the 9400 Series is established using a proven ‘Type 7’ magnetic coupling, outside of the flow stream, to drive a variety of accessories in a number of applications. Electronic registration for the 9800/9900 Series is provided through the Brodie electronic register. This microprocessor based instrument is used for flowrate indication and totalization. It is capable of transmitting a factored analog current output signal (4-20 mA) used to drive standard process instrumentation.

ADVANCED ELECTRONIC FEATURES

Only available in the 9900 Model, the Smart Meter Manager™ provides an array of useful utilities:

- Automatic temperature compensation

- 4-20 mA (2-wire mass/volume) output with HART® communication

- User configurable and scalable pulse output

- Comprehensive alarms for both process flow and internal diagnostic checks

- Easy access programming

- 10-Point meter factor linearization